Lubrication With Oil Mist

Article by Aurel Mareș

Oil mist is generated using an oil mist generator. The oil mist is a mixture of air and oil in a ratio of 200,000 parts air to 1 part oil, with a droplet size below 3 microns. This mixture is non-explosive and does not fall under the category of VOCs (volatile organic compounds).

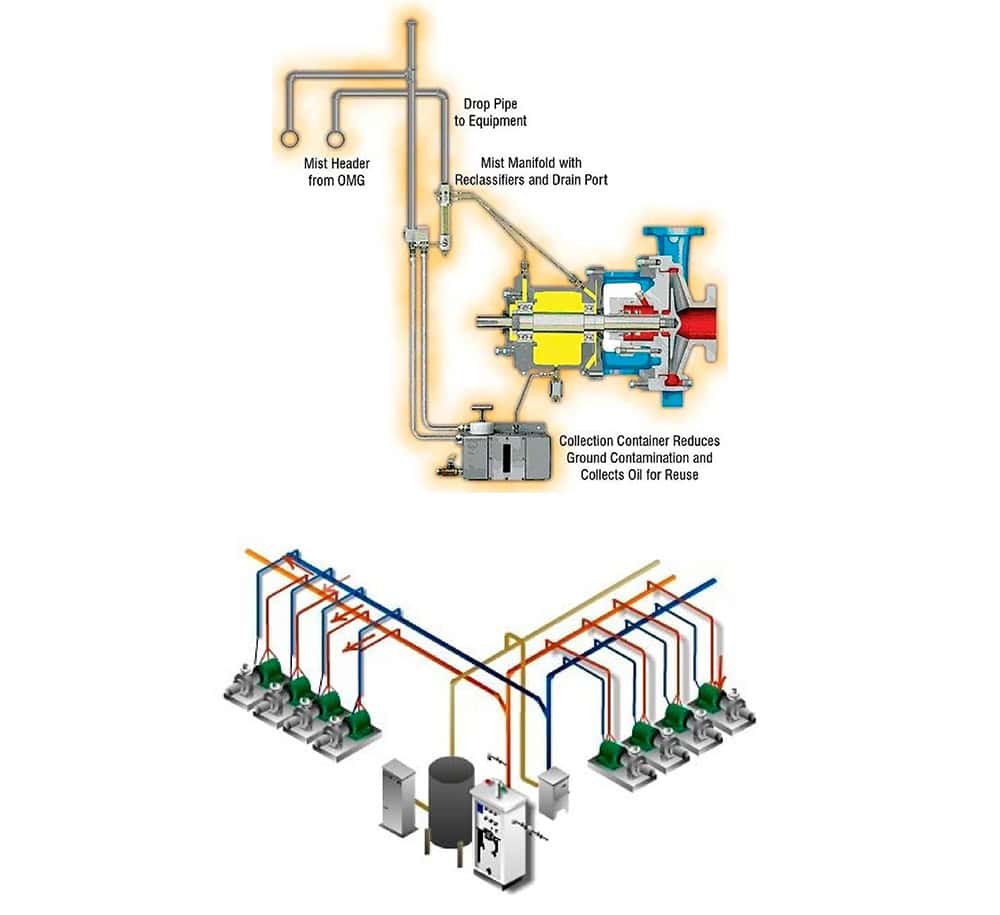

The mist is transported through system pipes by maintaining the minimum pressure necessary for transport (air + oil particles). The oil mist is distributed according to the size, type, and configuration of the bearing and is injected directly into the bearing. Once inside the bearing, the mist deposits on the metal surfaces of the bearing (rolling elements and raceways) and forms a lubricant film, which is continuously replenished by the mist supplying the bearing.

The principle of oil mist generation and its distribution within the bearing is shown in Fig. 1.

It is well known that lubrication is a key factor in ensuring the reliability of dynamic equipment, and oil mist lubrication is one of the most effective solutions. But how is the oil mist produced, and how does such a system operate?

Advantages of oil mist lubrication

Oil mist lubrication systems are globally recognized and have been in operation for over 50 years, with the earliest references in literature dating back to 1940. Oil mist lubrication offers the following benefits:

- The same lubricant can be used for all types of rolling bearings. It can also be applied to sliding bearings, gearboxes, or other mechanical transmissions, maintaining or replacing the existing lubrication system depending on the application.

- Lubrication conditions are improved as the lubricating environment remains uncontaminated. Slight overpressure in the bearing prevents the entry of contaminants (solid, gas, or water vapor). During startup, the bearing components are continuously lubricated by the mist, even above the oil level.

- Lubricant consumption is significantly reduced.

- Bearing temperatures are lowered between 100°C and 300°C, extending bearing and equipment life by maintaining minimal vibration and original clearances.

- Energy consumption is reduced by preserving initial clearances and replacing grease or oil bath lubrication with the oil mist film.

- The oil mist system can serve all equipment in a coverage area, with configurable generator capacity.

- In the unlikely event of a generator failure, the existing oil mist volume maintains lubrication for several hours, preventing bearing damage.

- Maintenance staff are relieved from replacing oil or performing equipment interventions and can focus on other tasks.

- Oil mist ensures full and effective conservation of equipment stored long-term until installation.

- Rolling bearings using oil mist lubrication can reach an estimated service life of 100,000 operating hours, according to certain equipment manufacturers.

The API 610 standard (Centrifugal Pump for Petroleum, Petrochemical, and Natural Gas Industries) includes recommendations for conditions that equipment manufacturers must ensure when oil mist lubrication is applied.

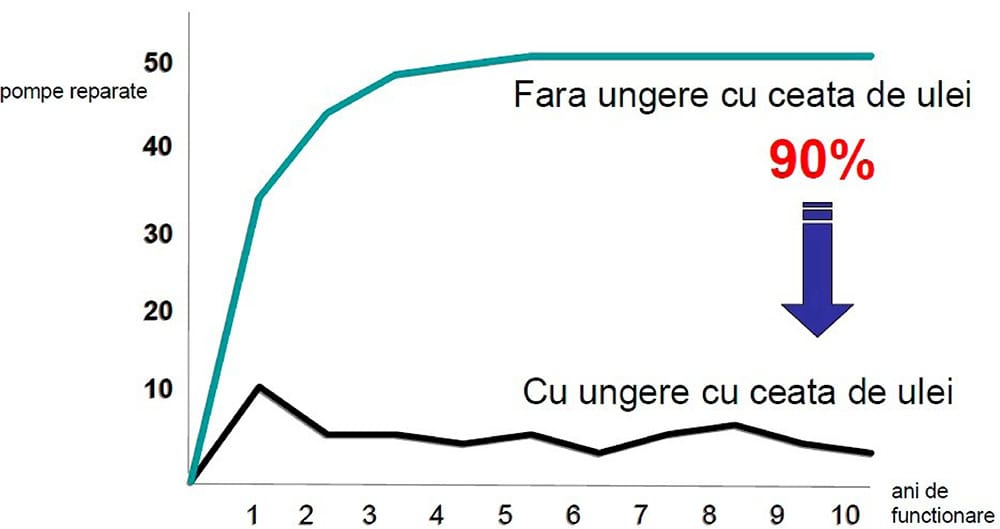

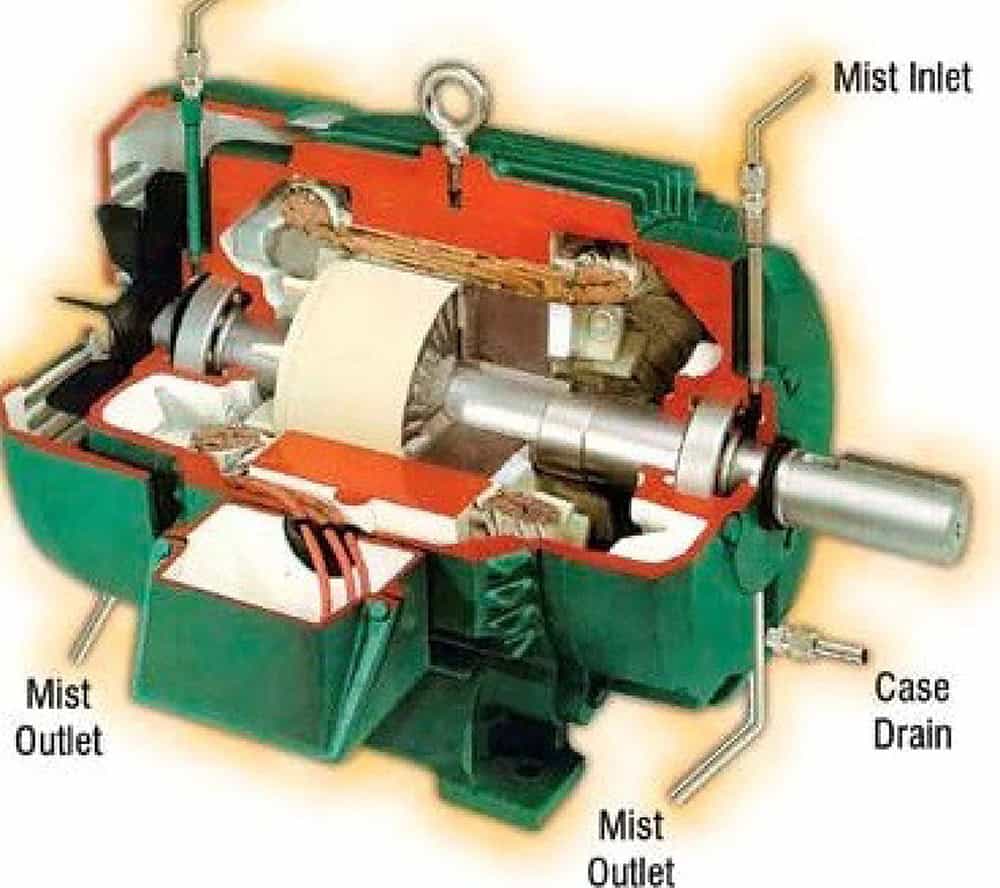

Comparative statistics between systems with and without oil mist lubrication are presented in the Hydrocarbon Processing publication (August 2008). Fig. 3 shows the number of pumps repaired in two similar Olefins plants, each with 200 pumps. Fig. 4 presents a study over three and a half years showing bearing failures in electric motors at two refineries. The bearing lubrication solution for electric motors is shown in Fig. 5.

Conclusion

Implementing an oil mist lubrication system leads to:

- Increased equipment reliability

- Reduced energy consumption

- Reduced lubricant consumption and variety

- Significantly extended service life

- Lower maintenance costs

- Fewer failures

- Enhanced operational safety

- Improved environmental conditions

About the author

Aurel Mareș has been with Ludan Engineering since 2013 as Technical Director. Ludan Engineering is an engineering company offering complete, multidisciplinary industrial solutions within EPCM projects (design, procurement, construction supervision, and management) or turnkey projects for various industrial sectors, including petrochemical, chemical, refining, agriculture, environmental protection, and more. Previously, Aurel Mareș was involved in maintenance and reliability projects in Romania and internationally.