Focus on PID Performance

The Financial Benefits of Optimised Regulatory Control

The purpose of any enterprise is to contribute to the creation of profit for its owners. In order to reach the maximum achievable profit, however, it is essential that each plant, each unit operation, and each individual piece of equipment functions at peak performance during all phases of production. In a broad sense a facility’s regulatory control systems are primarily responsible for fulfilling this task. Regulatory control systems must manage all aspects of an enterprise’s production resources — both effectively and efficiently — in order to maximise the amount of production output while minimising the use of production inputs. In spite of the fundamental role played by regulatory control systems, they are typically overshadowed by others that are routinely deemed more important.

Achieving optimal productivity implies both establishing and maintaining the optimal performance of each component from the bottom to the top. Hence the importance of continuously monitoring and optimising the performance of an enterprise’s regulatory control systems is an essential starting point. The value of doing so can be significant.

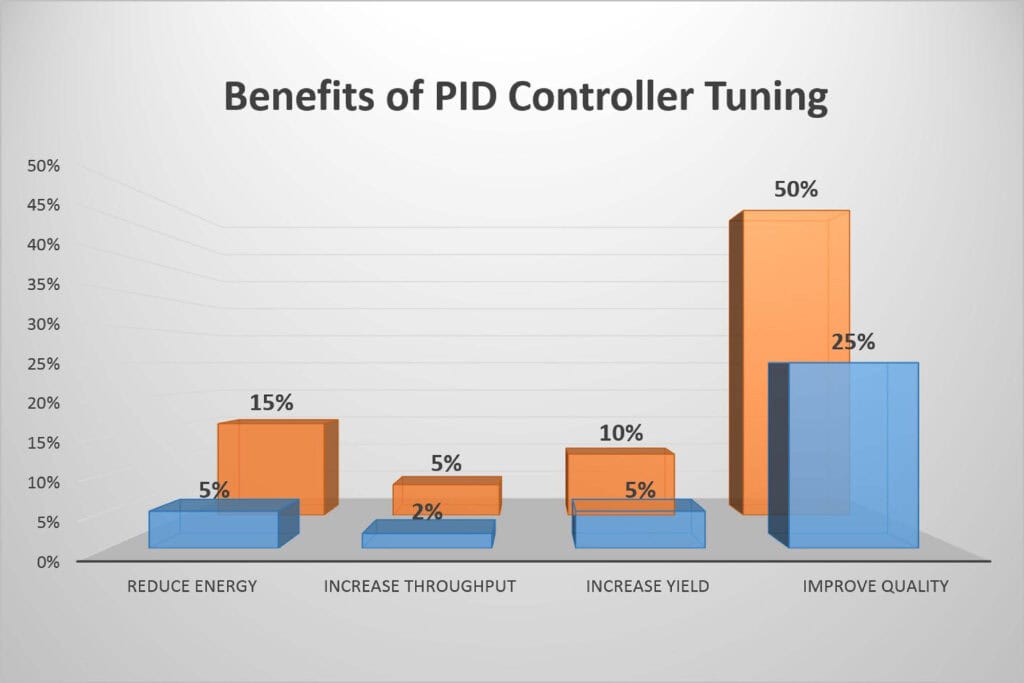

The Carbon Trust (www.carbontrust.com) performed extensive research that highlighted the economic benefits of basic regulatory controller tuning (i.e. PID tuning). The Carbon Trust is an independent organisation that supports research focused on sustainability and carbon reduction. The Carbon Trust promotes strategies and technologies that improve resource efficiency and that reduce carbon emissions. The benefits of regular PID controller tuning as documented by the Carbon Trust included reductions in energy consumption of 5%-15%, increases in throughput of 2%-5%, increases in yield of 5%-10%, and improvements in quality of 25% to 50%.

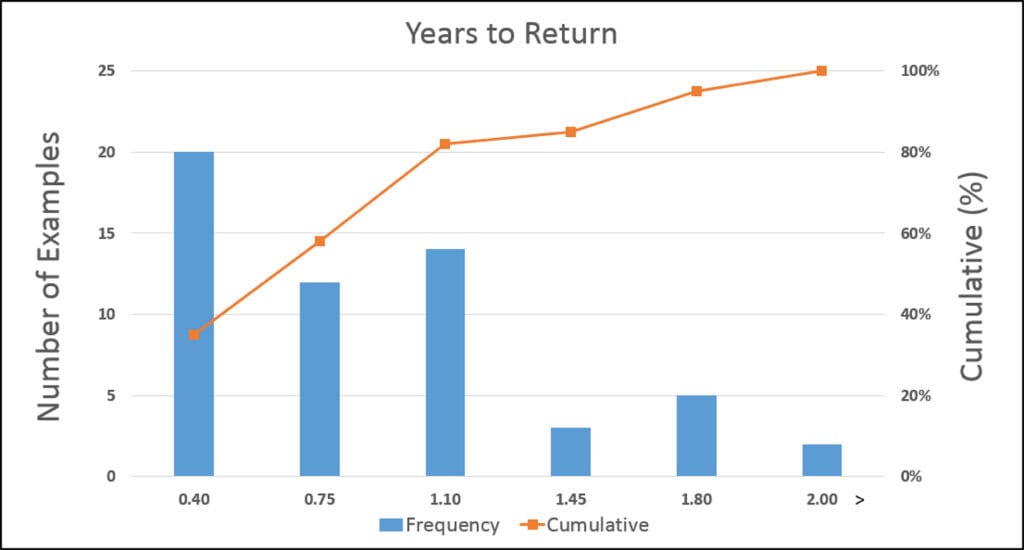

The investment in control loop performance monitoring and optimization is relatively low. Equally important the payback period is short. All production facilities participating in the Carbon Trust’s study achieved payback in less than two (2) years with over 50% achieving that goal in under nine (9) months. While some participants employed advanced control techniques the majority of participant benefits were realised simply by making sure that existing PID control systems were both functioning and tuned properly.

Oil refineries are an area where substantial benefits have been realised by improving basic closed loop control. For example, on one project the following gains were achieved:

- Valve movement was reduced, saving ~£10,000/year in compressed air costs;

- Energy savings of £200,000–£300,000/year were achieved on energy intensive processes;

- Targeted maintenance during shutdowns and normal operations reduced costs by up to £300,000/year;

- Advanced control and real-time optimizers led to increased profits of ~£80,000/year.

Reflecting on all of these added gains it is the final bullet that most clearly illustrates the importance of ensuring that basic control systems are working properly when advanced control systems are employed. If they are not taken into consideration, then the associated benefits can easily be lost.

While not part of the Carbon Trust’s study a wide range of benefits from the use of both PID controller tuning and control loop performance monitoring technologies have been documented, including the following:

- A petrochemical plant reduced the cycle time of its core batch production process from 133 minutes to 19 minutes through traditional PID controller tuning.

- A manufacturer of devices for the auto industry reduced the cycle time of its multi-zone furnace heating treatment process by 9.3% which resulted in an increase of 13.5% in production capacity.

- By tuning steam flow PID controllers a refinery reduced its use of steam and realised a profit of ~$30,000/year even before tuning the facility’s other critical process loops.

It’s important to keep in mind that the performance of an enterprise’s regulatory control loops changes with time. Performance of regulatory loops will degrade over time due to a variety of factors. Some common causes include:

- Equipment wear and tear, fouling etc.;

- Changes in production load and throughput;

- Differences in raw material quality;

- Adjustments to the plant’s economic targets.

As a consequence, continual monitoring and assessment of regulatory control loop performance is a must if the goals are to keep the enterprise’s regulatory control systems at peak performance and to maximize profit.

References:

- CG0005 — Companion Guide 5, “Invest in Control—Payback in Profit”, The Carbon Trust;

- GPG346 — Good Practice Guide, “Improving the Effectiveness of Basic Closed Loop Control Systems”, The Carbon Trust;

- GPG215 — Good Practice Guide, “Reducing Energy Costs in Industry with Modern Control Techniques”, The Carbon Trust;

- Various Success Stories, “Solving Customer Challenges”, Control Station, Inc.