Operations & maintenance

How can

we help

Maximizing performance. Extending life. Ensuring reliability.

Your facility’s true value emerges through sustained operational excellence. Ludan’s operations and maintenance services ensure that your assets continue delivering optimal performance long after commissioning. We combine predictive technologies with proven maintenance strategies to maximize uptime, extend asset life, and optimize operational costs. Our teams work as an extension of yours, providing the expertise, systems, and support needed to maintain peak performance while adapting to changing demands and opportunities.

Operations support

- Plant operation optimization

- Process troubleshooting

Maintenance services

- Preventive maintenance programs and application

- Predictive maintenance implementation

- Shutdown planning and execution

- Spare parts management

Projects

Other Ludan Engineering operation & maintenance projects

Monitoring pressure equipment according to ISCIR norms, by IBM Maximo application

Client: ROMPETROL S.A.

MAXIMO implementation

Client: NIS a.d. Novi Sad

Maintenance management by MAXIMO

Client: AZOMURES S.A.

Production data monitoring system

Client: AZOMURES S.A.

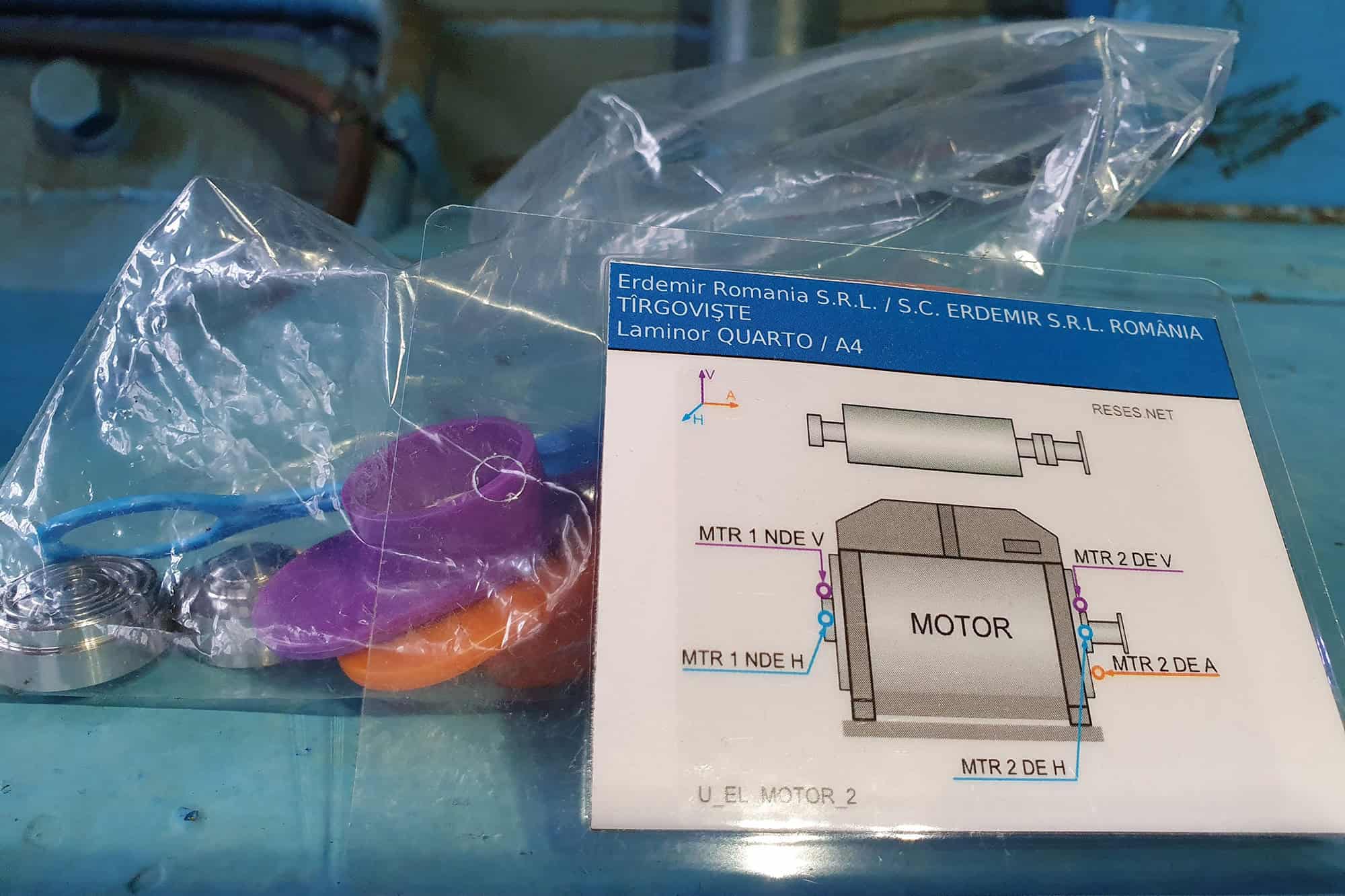

Equipment monitoring and diagnosis

Client: FERRO Performance Pigments, Romania

OsiSoft plant information implementation study

Client: AZOMURES S.A.

Integrated control system development for NPK crystallization operations

Client: AZOMURES S.A.

Control system modernization for butadiene production plant

Client: Energy Bio Chemicals S.A.

Dynamic equipment monitoring

Client: FORD S.A. Romania

Predictive maintenance system for fan vibration and thermal monitoring

Client: WIENERBERGER S.A.

Our

approach

We take a proactive view of maintenance — not just reacting to problems but helping prevent them. Using advanced diagnostics and real-time data, we identify risks early and extend asset life without compromising performance.

Our engineers integrate closely with client teams to deliver reliable support and knowledge transfer, so systems remain safe, efficient, and fully operational over time.

24/7

technical support across 15+ facilities

30+

predictive maintenance systems implemented

90%

operational uptime in supported sites

How we

bring value

Sustained system performance

Our teams support day-to-day operations with ongoing technical assistance — ensuring systems run efficiently, safely, and without interruption.

Predictive, not reactive

Using advanced diagnostics and monitoring tools, we anticipate maintenance needs before problems arise, reducing downtime and repair costs.

Commissioning and start-up support

We assist with initial system commissioning and transition to operation, ensuring performance is optimized from the beginning.

Trained on-site teams

Our engineers work alongside client teams or remotely, offering flexible support that fits the operating environment.

Asset longevity and ROI

Through planned maintenance, data analysis, and performance tracking, we help extend asset life and protect long-term value.

Contact

Let’s discuss your next project!

Get in touch with our certified engineering team.