Ultrasonic Inspection: Enhancing Predictive Maintenance and Asset Reliability

Article by Aurel Mareș

Overview

In modern industrial environments, predictive technologies play a critical role in ensuring asset performance, with ultrasonic inspection standing out as a key method. This technology enables early detection of potential equipment failures, enhances maintenance efficiency, and supports operational safety across electrical, mechanical, and process systems.

Ultrasonic inspection: enhancing predictive maintenance

Predictive technologies are key to maintaining high performance in industrial environments, and ultrasonic inspection plays a major role. This article briefly explores the advantages of ultrasonic inspection, with references to figures included for visual guidance.

Understanding sound waves

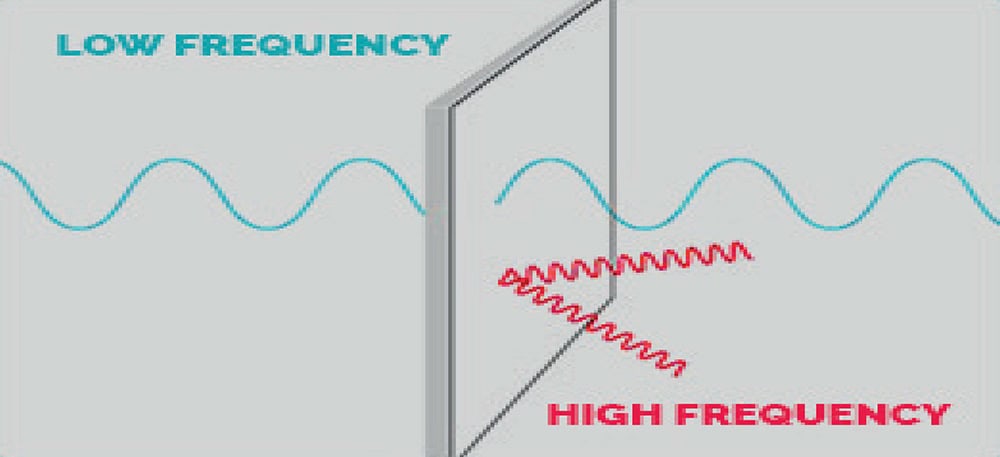

Sound originates from vibration, which propagates through elastic media—solid, liquid, or gas—within a frequency range of 20–20,000 Hz, perceivable by human hearing. Sound is not directional and can penetrate solids, making localization difficult (Fig. 1). Low- and high-frequency sound propagation is illustrated in Fig. 1.

How ultrasonic technology works

Ultrasound refers to high-frequency sounds ranging from 20–100 kHz. Key characteristics include:

- Directionality, enabling precise localization;

- Functionality in noisy environments;

- Reflection upon impact with solid media, rather than penetration;

- Reduction in intensity over distance, aiding source localization;

- Evaluation of equipment condition.

Applications of ultrasonic inspection

1. Leak Detection

- Pressurized or vacuum systems for air and gases;

- Heat exchangers;

- Tanks and boilers.

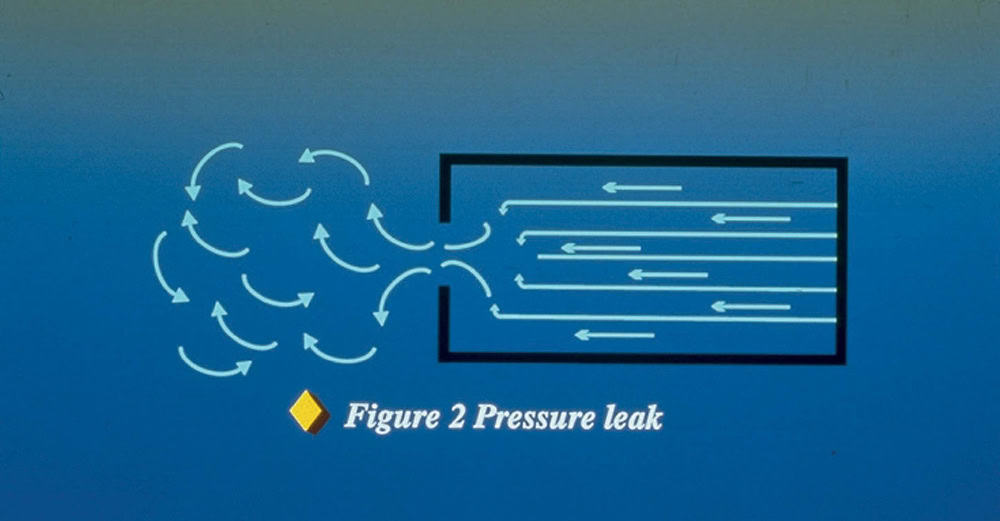

Turbulent gas flow (Fig. 2) is detectable via ultrasonic inspection, whereas laminar flow is not.

2. Valve Inspection

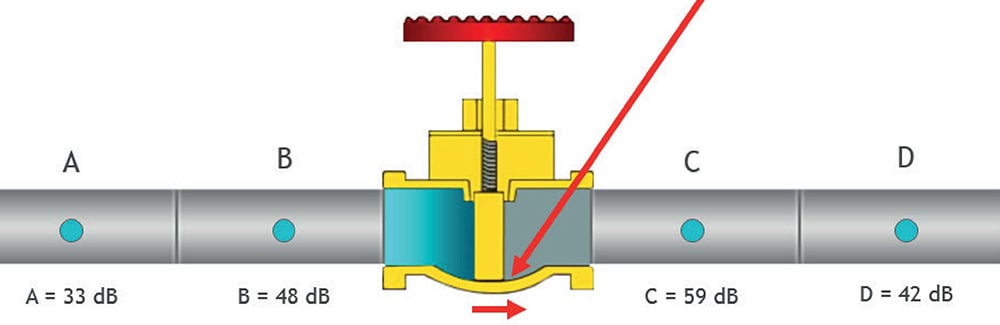

- Checking isolation at closed positions (Figs. 4–6);

- Assessing operation of condensate pots (Fig. 7).

Analysis of readings at points A, B, C, and D determines valve performance and identifies if further inspection is needed.

3. Electrical Inspection

- Medium, low, and high-voltage installations;

- Transformers;

- Circuit breakers.

Can detect corona effects, partial discharges, component fixation, and arcs.

4. Mechanical Inspection

- Bearing condition (Fig. 8);

- Lubrication (Fig. 9);

- Cavitation in centrifugal pumps;

- Conveyor belt inspection.

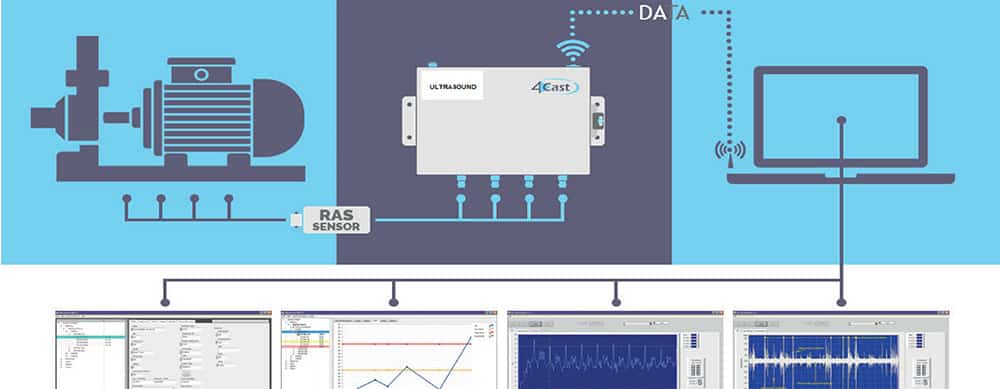

5. Online Monitoring

- Electrical panels;

- Valves and bearings via permanently installed sensors;

- Ethernet-based bearing monitoring (Fig. 10).

Integration with CMMS

When a Computerized Maintenance Management System (CMMS) is implemented, data standardization and predictive technology integration enable advanced maintenance diagnostics and proactive decision-making.

Predictive maintenance benefits

Ultrasonic inspection allows early defect detection and supports:

- Bearing and lubrication issue identification;

- Electrical equipment defect detection;

- Mechanical inspections;

- Leak detection;

- Valve inspection;

- Continuous online monitoring;

- Integration with robust CMMS platforms (Fig. 12 illustrates P–F curve positioning).

Conclusion

Ultrasonic inspection is a versatile, high-impact tool for predictive maintenance, helping industrial operators improve equipment reliability, reduce downtime, and extend asset life. When combined with comprehensive maintenance systems, it empowers organizations to operate proactively and efficiently.

About the Author

Aurel Mareș, Technical Director at Ludan Engineering since 2013, brings extensive expertise in maintenance and reliability. Ludan Engineering delivers complete EPCM and turnkey solutions across sectors including petrochemical, chemical, refining, agriculture, and environmental protection, providing multidisciplinary engineering excellence worldwide.